Horizontal Rack Safety Nets

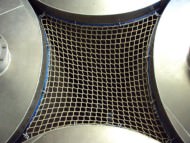

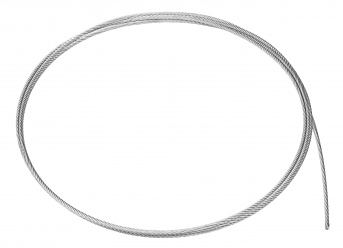

Safety nets can be used in high-bay shelters for fall protection. The net is stretched horizontally within racking systems to protect people whose fall could not be prevented. The nets thus protect against injuries due to deeper fall. The requirements of these networks are described in Annex 2 of DGUV Rule 101-011. The net gets mounted with a steel cable of a minimum diameter of 6 mm, mounting accessories with sufficient tensile strength between the net and the steel cable (snap hooks or shackles) and a cable tensioner with a tensile force equal to the rope diameter. Please also note our guidelines for rack safety nets.

High-quality workmanship, looks good too. Everything is perfect.

So that goods do not fall down

Product is good. I am very satisfied

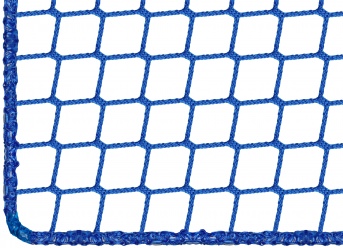

according to DGUV rule 101-011

with reinforced selvage cord

Rope Diameter: 5.0 mm

Mesh Size: 45 mm

Material: high tenacity polypropylene, knotless

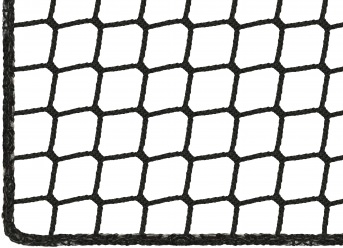

according to DGUV rule 101-011

with reinforced selvage cord

Rope Diameter: 5.0 mm

Mesh Size: 45 mm

Material: high tenacity polypropylene, knotless

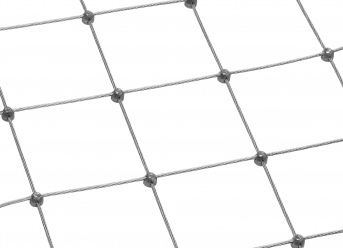

galvanized steel cable

with aluminium clamps

Rope Diameter: 3.0 mm

Mesh Size: 100 x 100 mm

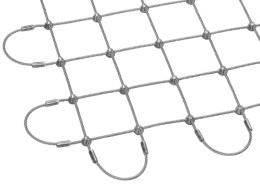

stainless steel cable

with stainless steel clamps

Rope Diameter: 3.0 mm

Mesh Size: 100 x 100 mm

How To Secure Shelf Racks?

Safety nets are used in high-bay warehouses to protect goods from falling out of the rack and people from falling objects. They are placed vertically to close the rack and horizontally to protect people from injuries caused by falling. According to the German Workplace Guidelines ASR 12/1-3 and ASR 17/1.2, protective devices such as safety nets are required in higher workplaces and traffic routes that are not adequately protected. DGUV Regulation 108-007 and DGUV Regulation 101-011 describe the requirements for safety measures in storage facilities and the use of safety nets in high-bay racking systems.

Another important use of nets in high-bay warehouses is to protect people from falling. These nets are stretched horizontally to protect people who cannot be prevented from falling. These nets prevent injuries caused by deeper falls.

How To Create A Pass-Through Protection?

Horizontally tensioned nets can be used as passage protection. Both textile safety nets and wire rope nets with a correspondingly small mesh size can be used for this purpose. Vertical protection as preventive protection is preferable. If the structural or technical conditions do not permit this, safety nets in accordance with DGUV regulation 101-011 or wire rope nets can also be clamped horizontally.

You can find more information on safety nets in technical installations in our rack safety net guidelines.

How To Mount A Pass-Through Protection?

The installation of a pallet rack safety net requires the use of steel ropes with a minimum diameter of 6 mm. These are tensioned in front of the surface with rope tensioners to form a frame for the safety net. The steel ropes must be locked between the anchorage points in such a way that stretching in the direction of the net construction is restricted, e.g. by guiding through ring eyelets. The distance between the guiding and anchoring points must not be greater than 1.00 m. The net is then fastened to the steel cable frame with the edging. Sufficiently tension-resistant fasteners such as safety snap hooks or shackles must be used for this purpose. The distance between the attachment points of the net must not exceed 35 cm.

The construction of the shelf safety net must be attached to load-bearing points. Each suspension point must have been calculated for a characteristic load of at least 6 kN at an angle of 45 degrees. Three characteristic loads of 4 kN, 6 kN and 4 kN at the most unfavorable point shall be considered to ensure the design of the structural components. The distance between the suspension points must not be more than 1.00 m. The forces that occur must be able to be safely absorbed and transmitted by the suspension points and structural parts.

Recommended accessory

High-quality workmanship, looks good too. Everything is perfect.

So that goods do not fall down

Product is good. I am very satisfied

modified eCommerce Shopsoftware © 2009-2026

Code & Implementation: Rehm Webdesign