Custom-Made Steel Wire Rope Nets

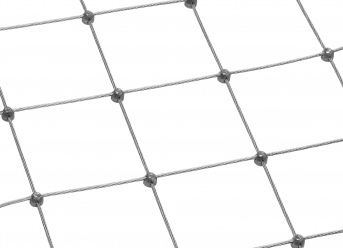

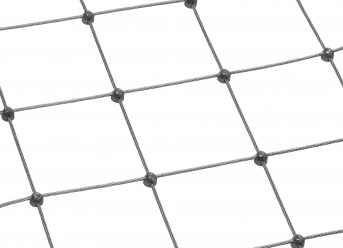

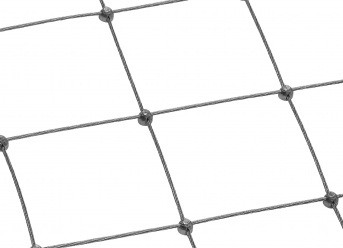

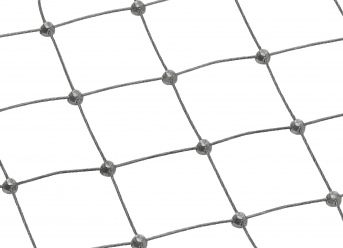

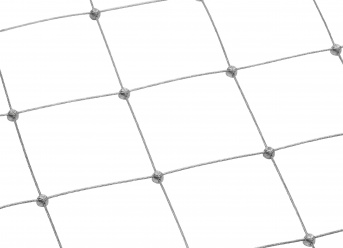

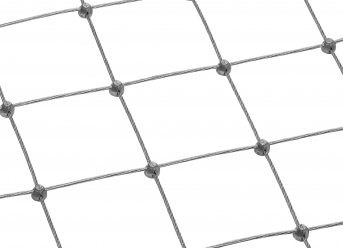

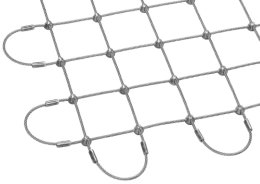

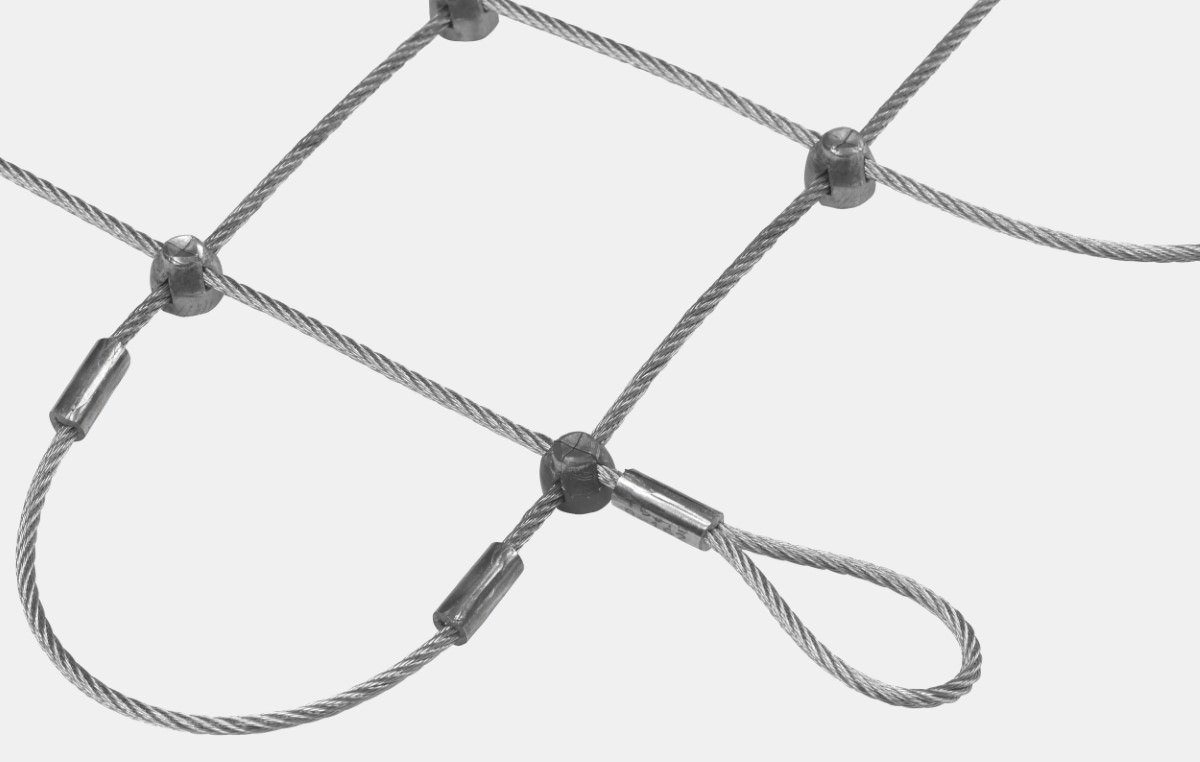

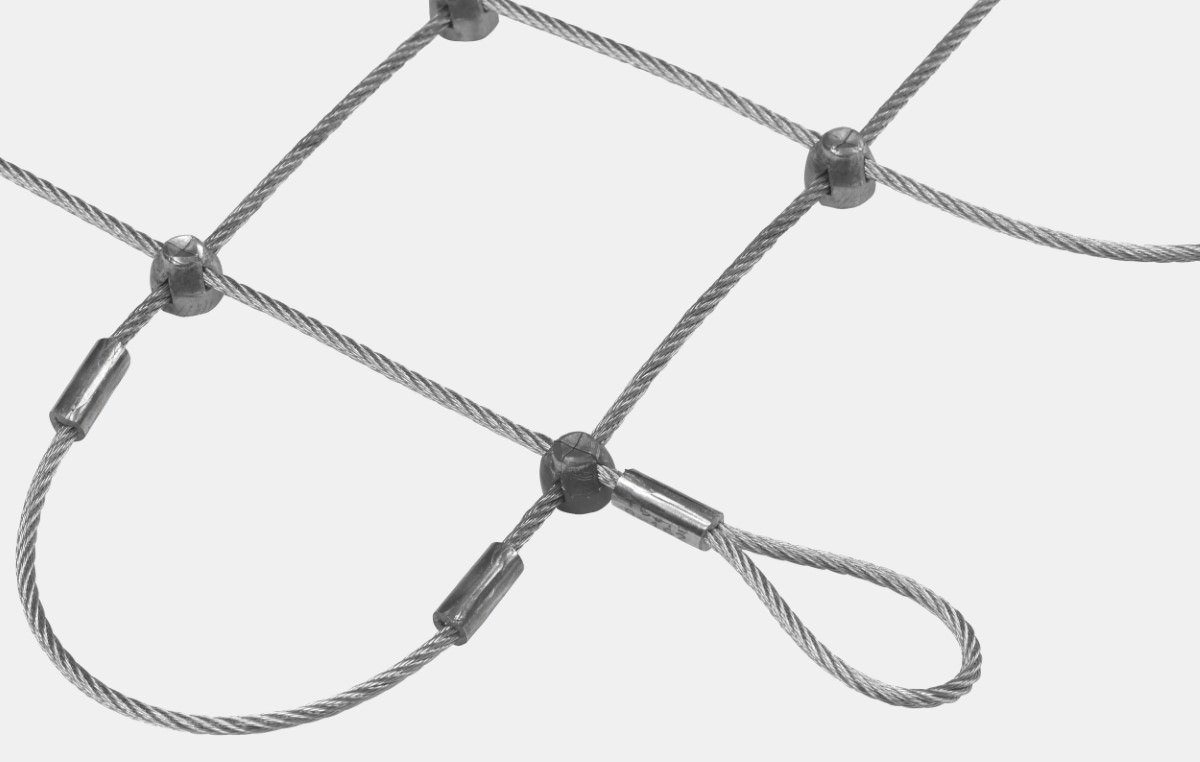

Our wire rope nets consist of individual steel ropes, which are between 1.5 and 8.0 mm thick. The ropes are brought into a net shape and pressed using clamps at the crossing points to achieve a highly resilient connection. At the edge, the characteristic loops are created all around, which serve as an attachment point or to hold a steel cable running all around. We can offer the steel wire nets in various mesh sizes and mesh shapes with a size between 20 and 300 mm.

The basic materials are galvanized wire ropes with aluminium clips or stainless steel ropes with aluminium or stainless steel clips.

The maximum width produced by the machines is 5 meters. Wider nets would be made out of connected multiple nets. The length is continuous and is not limited in terms of production technology. Depending on their width and design, the nets can be made up to a total weight of approx. one ton. A continuous adjustment of the mesh size or a special assembly in the edge area is also possible. If you have any further questions, please contact us!

Sub-Categories

Quick Filter Material

Quick Filter Mesh Position

Quick Filter Mesh Size

Quick Filter Rope Diameter

Steel Wire Nets for Every Application

Wire rope nets are characterized by high load capacity. The nets made of steel cables offer excellent protection against extreme weather conditions. So the expression "having nerves of steel" is no coincidence, because these nets withstand great forces and convince in terms of durability in everyday use. Further advantages of our rope nets are:

- flexibility

- aesthetics

- high quality

- customisability

The fields of application of the nets include, in particular, fall protection and the protection of architectural monuments. You will therefore find wire rope nets above all:

- in building construction,

- in parking garages,

- at sports facilities,

- in zoos,

- as a plant climbing aid,

- as a railing filler.

Whether as a business customer or privately in your own home and garden - use the nets to separate individual areas from each other, prevent unauthorized access or secure impassable terrain.

We provide you with high-quality nets that you can configure individually with regard to their rope strength, mesh size, length and intended use. With our filter and sorting options you can choose the right wire net for your project.

Popular Wire Netting

Finding the Right Wire Netting

Steel Or Stainless Steel: Which Material For Your Net?

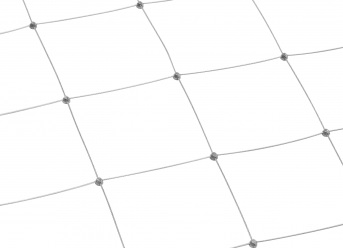

Steel cable nets or stainless steel nets? The choice of material for the net depends entirely on the intended use. The following principle applies here: If the wire net is to be visible or if it is located in areas subject to weather conditions (e.g. salty sea air), choose stainless steel. Such a net is characterized by its good stability and, as a design element, can also provide visual highlights in the space used. An advantage of wire rope nets is their rope curvature, which leads to their high flexibility. A shiny silver stainless steel net can thus achieve an aesthetic effect in addition to its function.

Wire Rope Nets: Choosing The Right Rope Strength

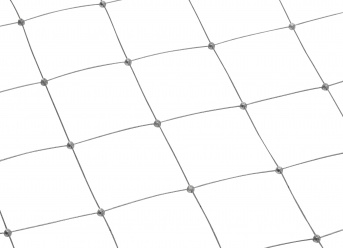

The selection of the right rope strength and the displacement resistance of our cross clamps depends on the area of application of the wire rope net. The central question here is: How strong should your net be? While the lowest rope strengths are sufficient for a scaffold for plants, the rope strength becomes more and more important the more it serves as a safeguard.

As a general rule, if you want to build a protective barrier with your steel cable nets, the load capacity of the nets does not depend solely on their rope strength. The load-bearing capacity table of the German Social Accident Insurance (DGUV) assumes symmetrical loading of ropes when specifying the rope strength. To ensure that the forces remain controllable, it is also important to avoid a sling angle exceeding 60°.

Especially rope nets for vertical protection should therefore be checked regularly for stability. Maintenance is particularly necessary when a load case has occurred. Maximum tensile strength as well as the displacement strength of the clamps are specified in kilonewtons. The higher the specified kilonewton unit, the more resilient the nets are. For example, our nets with a rope thickness of eight millimeters have a minimum breaking strength of 44.7 kN.

The Correct Mesh Size Of Your Wire Rope Net

The mesh size is also essential for efficient use. If you want to use your rope net as predator or bird protection, a small meshed net is a good choice. This way, animals can neither enter the separated area from the outside nor escape from the enclosure. Also, keep in mind to choose the width of the meshes so that animals do not get caught in the steel cable netting and injure themselves. A fine mesh wire net can also be useful for vertical protection. Here it depends on the size of the objects you want to catch.

Calculate The Correct Dimensions Of The Wire Rope Nets

Do you know the optimal dimensions of your wire mesh? A measurement is a good start - but for the choice of the size you have to consider other things!

First of all, the following is important for calculating the dimensions: The width of the stainless steel or steel cable net is measured from the inner edge of the outermost loop to the inner edge of the loop at the opposite end. When installing the safety nets, there should only be a slight tension on the net. This will cushion living beings or objects in the best possible way in the event of an impact.

Frequently Asked Questions

- What Are Steel Wire Rope Nets Made Of?

- Where Are Steel Wire Nets Used?

- How To Install Wire Rope Nets?

Wire rope nets are nets made of steel or stainless steel ropes, which can vary in thickness. We offer nets with steel ropes from 1.5 to 8.0 millimeters in diameter. The wire ropes of the nets are pressed in such a way that they reach their maximum load capacity. Standard manufacturing creates loops on the edge area, which can also be used for fastening or to accommodate a steel cable running all around. Clamps made of aluminium and stainless steel are used for the crossing points of the wire rope nets. aluminium clamps are used for both steel cable nets and stainless steel nets. Stainless steel clamps, on the other hand, are usually used only on nets made of the same material.

Our steel nets from machine production have a width of five meters. If you would like a larger span width, we can make additional nets. In addition, we are happy to make other special designs for you.

Our nets also offer you numerous options when it comes to mesh size: Here you will find nets with meshes ranging in size from 20 to 300 millimeters. Of course, you can also get a mesh size that is continuously adjusted for you on request.

Wire rope nets are characterized by their stability and durability and are versatile. Decisive for the selection of the right net are: Material of the net, the material thickness, as well as the mesh size and dimensions.

Whether you want to use your wire netting to create a protected outdoor enclosure for your pets or rely on a steel net with a high rope strength to secure an attraction in an amusement park - we can provide you with the right net for private and commercial use.

Steel Or Stainless Steel: Which Material For Your Net?

Steel cable nets or stainless steel nets? The choice of material for the net depends entirely on the intended use. The following principle applies here: If the wire net is to be visible or if it is located in areas subject to weather conditions (e.g. salty sea air), choose stainless steel. Such a net is characterized by its good stability and, as a design element, can also provide visual highlights in the space used. An advantage of wire rope nets is their rope curvature, which leads to their high flexibility. A shiny silver stainless steel net can thus achieve an aesthetic effect in addition to its function.

Stainless steel nets are ideal for:

- elegant fences,

- railings,

- aesthetic barriers.

Their areas of application are thus often:

- playgrounds,

- hiking trails,

- zoos.

If, on the other hand, you need maximum load capacity, the best choice is a galvanized steel net. Such a net you can also use well, if you want to plant it with a hedge or other plants. The material is more resilient than the nets made of stainless steel. Such steel cable nets can be used here especially well:

- as scaffolding for climbing plants,

- as fencing indoors and outdoors,

- as rockfall protection.

You mount wire nets by using the loops of every second mesh as a mounting base. Ideally, there is already a substructure or other form of a frame. This will allow you to hang your wire rope net in hooks or eyelets. If there is none, it may make sense to attach the wire rope net to steel or aluminium tubes and thus create a frame yourself. In some cases, there are already recesses for this purpose, otherwise drill them in first. For this demanding activity, you should use a drill that is explicitly suitable for steel or stainless steel pipes.

Now pass a loop through the respective frame and screw it. Note that such a method of attachment can lead to a change in the length of the loops. This is especially the case if the net is loaded selectively. Therefore, on request, we also offer wire nets that run out at their edges with slings. We can screw or crimp these to the ends of the wire rope.

Whichever method of assembly you choose: Be sure to carefully assemble the net of wire ropes without distorting it.

Sub-Categories

Our Benefits

Sub-Categories

Quick Filter Material

Quick Filter Mesh Position

Quick Filter Mesh Size

Quick Filter Rope Diameter

modified eCommerce Shopsoftware © 2009-2026

Code & Implementation: Rehm Webdesign