Guardrail nets, also known as scaffold nets or side protection nets, are mainly used for roof work. Other areas of application are work on platforms or bridge construction. They are used for direct fall protection of persons. When nets are used, the intermediate rail can be dispensed with. They are installed in roof safety scaffolds or in the working level of facade scaffolds.

Side protection or scaffold nets are classified as safety net system U. This protective net system designates "protective nets in supporting structure for vertical use".

Within this category, a further distinction is made between 4 net classes depending on the minimum breaking energy, which must meet the following requirements:

| Net Class | Max. Mesh Size | Required Minimum Energy Absorption

When New |

|---|

| A1 | 60 mm | 4.14 kJ |

| A2 | 100 mm | 4.14 kJ |

| B1 | 60 mm | 7.92 kJ |

| B2 | 100 mm | 7.92 kJ |

When testing static energy absorption, a test net with a size of 3.00 x 3.00 m must cover at least the aging of one year with a safety factor of 1.5. The guardrail nets available from us have a larger reserve than required and therefore offer the greatest possible safety (see table below).

| Net Class | Mesh Size | Energy Absorption | Max. Tensile Strength

of a Mesh |

|---|

| A1 | 60 mm | approx. 6.1 kJ | approx. 3200 N |

| A2 | 100 mm | approx. 4.8 kJ | approx. 3200 N |

| B1 | 45 mm | approx. 9.0 kJ | approx. 3200 N |

Guardrail nets must be stretched tightly. When used on scaffolds, the nets must be fastened to the scaffold spar. The nets must comply with class A2 according to EN 1263-1, the mesh size must not exceed 100 mm, and the energy absorption when new must be at least 4.14 kJ.

The product standard EN 1263-1 is authoritative for guardrail nets and safety nets in scaffolds. The requirements for the use and assembly of side protection nets are specified in DGUV information sheets 201-011 and 201-023.

Each scaffold net must be clearly marked in accordance with EN 1263-1. The following points must be included in the labeling:

- Manufacturer, supplier or importer

- Designation according to EN 1263-1

- Article designation (incl. net class, mesh direction, mesh size and net size)

- Month and year of manufacture

- Minimum energy absorption capacity of the test mesh. This already takes into account a loss of strength due to aging over a period of 12 months, as well as a general safety factor

- Test number of the testing institution that certified the net

With the links below you will find a leaflet of the BG Bau, the published regulation of the DGUV as well as further downloads on the subject of guardrail nets:

The scaffold erector is responsible for the safe erection, modification and dismantling of a scaffold. This also applies to work equipment and protective equipment such as safety nets.

The assembly of side protection nets in the course of scaffold erection must be supervised and monitored by a competent person. Qualified persons are, for example, persons who have completed vocational training in the scaffold erection trade and have sufficient practical work experience, certified senior scaffold erectors, certified scaffold erection crew leaders, certified foremen or persons who have comparable specialist knowledge and training in the building trade as well as sufficient practical work experience in scaffold erection.

The employer is responsible for assessing suitability and selecting the supervising person.

Scaffolding work and the assembly of side protection nets must be carried out by qualified employees. An employee is considered to be "qualified" if he or she has completed vocational training in the scaffolding erection, completed vocational training in the construction-site erection with required knowledge of scaffolding, or employees with comparable qualifications for whom the employer decides on suitability.

An employee is also considered qualified if he or she has sufficient practical work experience depending on the side protection net to be erected.

The employer is responsible for assessing suitability and selecting employees.

Every person using or working on the scaffold has a duty to cooperate in ensuring safety and health protection at the workplace. Every user of the scaffold should have been instructed in advance.

The users of a scaffold are also required to report any obvious changes detected during use to the respective supervisor. These changes include, for example, the improper installation or removal of side protection nets.

A scaffold net must be mounted tightly tensioned. When used as a safety barrier in roof safety scaffolds, an intermediate spar can be dispensed with.

The mesh must at least comply with net class A2 according to EN 1263-1. Accordingly, the mesh size must not be larger than 100 mm and the energy absorption when new must be at least 4.14 kJ.

Protective nets in scaffolds must be attached to the scaffold tubes on all sides. Ideally, the nets are attached to the scaffold tube mesh by mesh.

Alternatively, according to DGUV information 201-023, mesh-wise fastening may be dispensed with if the net is fastened to the edge at intervals of no more than 75 cm and the adequate load-bearing capacity of the net fastening has been demonstrated in the dynamic test in accordance with EN 1263-1, Paragraph 7.11.

Safety nets may only be changed in their dimensions by the manufacturer. It must be re-marked in the event of a change by the manufacturer. A safety net whose dimensions have not been changed by the manufacturer automatically loses its approval according to EN 1263-1.

| Montagevarianten |

![Scaffold Net Mounting]() | Direct Mounting on the Supporting Structure Direct mounting of the nets on the scaffold tubes is considered the standard variant according to DGUV information 201-011. The nets are attached mesh by mesh. |

![Scaffold Net Mounting With Strap Fasteners]() | Mounting with Quick Release Strap Fasteners A simple and quick way of mounting is by means of belt quick-release fasteners with a clamp lock every 75 cm. The straps can be connected directly to the edge of the net or used loosely. Some side protection nets in standard sizes are available with quick-release belt fasteners already sewn on. |

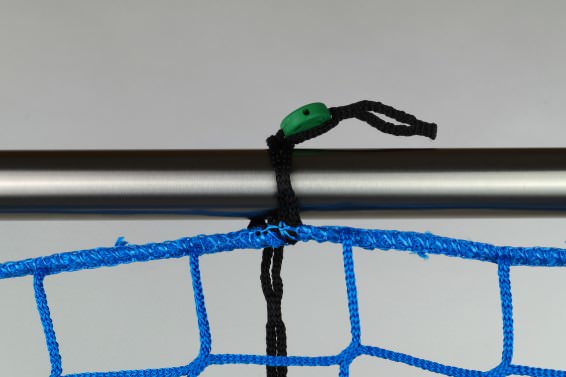

![Scaffold Net Mounting With Isilink-Clips]() | Mounting with Isilink-Clips The patented Isilink system is a simple mounting option for side protection nets that meets all DGUV requirements. The clips sewn to the net are placed around the scaffold tube at a maximum distance of 75 cm and closed with a button and buttonhole. All standard sizes are available with clips already sewn on. |

![Scaffold Net Mounting With Ropes]() | Mounting with Ropes Guardrail nets can be tied to the supporting structure by means of sufficiently dimensioned ropes. The rope should be threaded through the net and the supporting structure mesh by mesh. During installation, non-detachable knots must be used or the knots must be secured against unintentional loosening. |

CAUTION:

Fastening of side protection scaffold nets nets with cable ties or binding wire is not permitted. |

If two side protection nets meet at a point to be secured where there is no scaffold tube, the nets may be coupled.

For coupling, the nets are connected to each other at the joint by means of a coupling rope, mesh by mesh. Coupling ropes according to EN 1263-1 must have a breaking strength of at least 7.5 kN.

Alternatively, the net joint may also be executed without a connection if the two nets overlap by at least 75 cm.

Defects in work equipment, facilities, work procedures or work processes that could result in hazards for the employee must be reported immediately to the supervisor and may not be used further without approval.

If defects are found in safety nets or net accessories, these parts may only continue to be used if it has been determined by a competent person that safety is not impaired by the defects.

Examples of safety-related defects include:

- Damaged net edging

- Torn mesh

- Damage to the supporting structure

- Damaged fasteners

Damaged safety nets and net accessories may only be repaired by the manufacturer or persons designated by him. Only material with the same properties as the original material may be used.

Guardrail nets and net accessories must be stored appropriately between two periods of use. Appropriate storage is given if they are stored

- in a dry environment,

- protected from UV radiation,

- protected from heat, and

- not in contact with aggressive substances (e.g. acids, alkalis, solvents, oils).

As supplied, guardrail safety nets are approved in accordance with EN 1263-1 for a maximum of 12 months from the date of manufacture. This approval can be extended three times for a net with an aging test for a further 12 months in each case. The time of the last test or the date of the next test is indicated on the type plate attached to the net.

There are test meshes on each scaffold net that can be clearly assigned to the net. For testing, one of these test meshes is detached from the net and sent to a suitable test center or the manufacturer. There, a tensile strength test is carried out. If this so-called test does not fall below the minimum energy absorption capacity specified by the manufacturer, the test is deemed to have been passed. The approval is then extended for a further 12 months. Proof of this is provided by the testing body by supplying a new nameplate for the network and issuing a test report.

The test of the minimum energy absorption capacity must be carried out in accordance with EN 1263-1 and must not date back more than 12 months. The results of tests on safety nets in use must be verifiably documented by the contractor.

Products

Further Guidelines & Info Pages