Rack Safety Net Guidelines

| Safety nets are used in high-bay warehouses to prevent goods from falling out of the rack and to protect people on traffic routes from falling objects. The sides of the racking concerned are usually covered vertically in order to close the racking there - similar to a grid. |

| A second major application of nets in warehouses and racks is fall protection for persons. They are stretched horizontally to protect persons whose fall could not be prevented. The nets thus protect against injuries as a result of a deeper fall. |

| As a third variant, nets are used in racks or warehouses as separation nets. These are used to divide storage areas within industrial halls or to secure goods laterally against tipping over. Lateral securing is often useful for intermediate floors or mezzanines to protect the goods from a major fall if they tip over. |

According to these workplace guidelines, protective equipment such as safety nets must be installed at higher workplaces and traffic routes that are not adequately protected from falling objects by guardrails: Safety nets must be installed.

For personnel safety nets in high-bay racking systems, nets with properties analogous to EN 1263 (safety nets) are used. The requirements are described in Annex 2 of DGUV regulation 101-011. Special provisions for installation in high-bay racking systems are also defined there.

| Montagevarianten | |

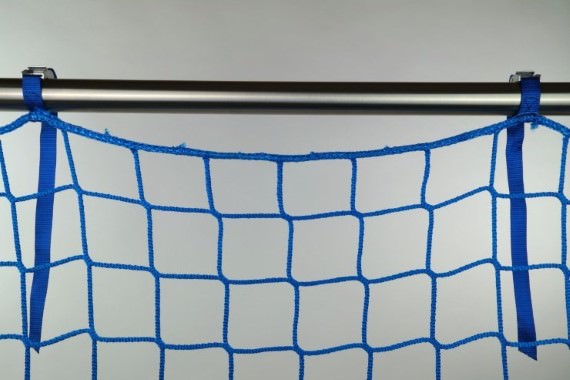

| Steel Cable Frame Steel wire ropes are stretched in front of the surface so that they form a frame for the safety net. The net can then be easily attached to the steel cable using snap hooks or shackles. |

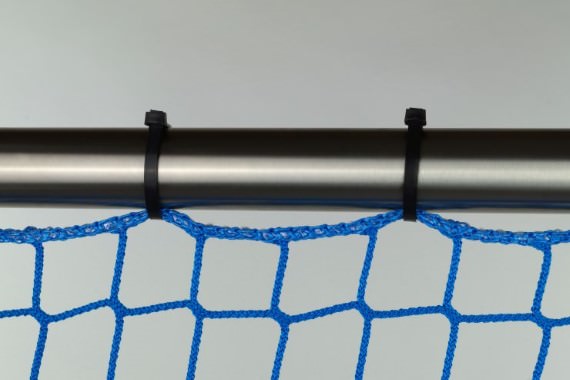

| Straps The net is connected directly to the shelf uprights and trusses using quick-release straps fasteners, disposable ties or similar. This type of fastening ensures quick assembly and disassembly. |

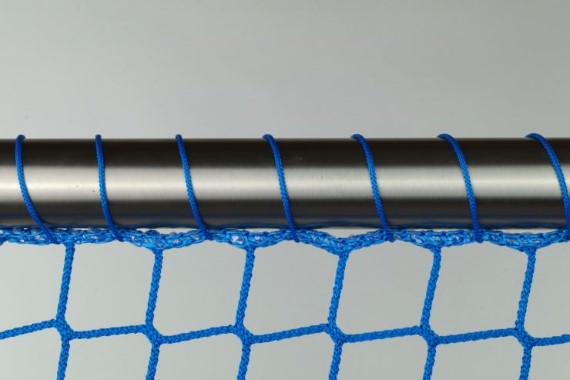

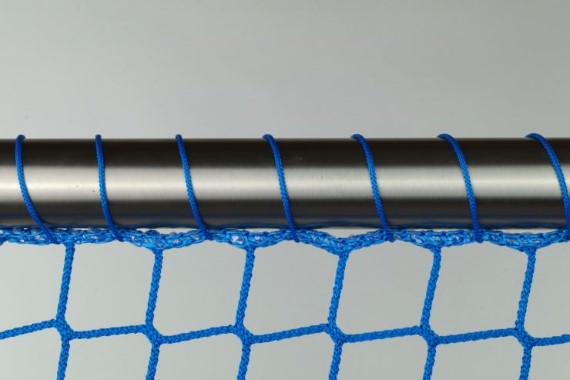

| Cords and Ropes The mesh is tied directly to the supporting structure mesh by mesh. With this type of fastening, a very uniform mesh pattern and load distribution is achieved. |

| Assembly | ||||||

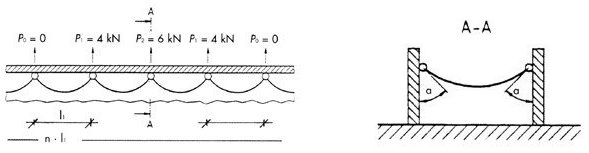

| A rack safety net is installed using steel ropes with a minimum diameter of 6 mm. These are tensioned with rope tensioners in front of the surface in such a way that they form a frame for the safety net. The steel ropes must also be locked between the anchoring points in such a way that stretching in the direction of the net construction is restricted. This can be achieved, for example, by guiding the steel ropes through ring eyelets. The distance between the guide and suspension points must not exceed 1.00 m. The net is then fastened to the steel cable frame with the edging. Sufficiently tension-resistant fasteners (e.g. safety snap hooks or shackles) must be used for this purpose. The distance between the attachment points of the net must not exceed 35 cm.

| |||||

| Assembly Variants | |

| Steel Rope and Weighting A steel cable is stretched at the required height. The net can be attached to it like a curtain by means of snap hooks. A steel cable can also be tensioned in the lower part. Alternatively, the net can hang freely. In this case, we recommend increasing the net width by approx. 10% and weighting the net with a lead cord or chain. |

| Stahlseilrahmen Steel wire ropes are stretched in front of the surface so that they form a frame for the safety net. The net can then be easily attached to the steel cable using snap hooks or shackles. |

| Straps The net is connected directly to uprights using quick-release strap fasteners, disposable ties or similar. This type of fastening ensures quick assembly and disassembly. |

| Leinen The mesh is tied directly to a supporting structure mesh by mesh. With this type of fastening, a very uniform mesh pattern and load distribution is achieved. |

| Downloads and Links |

|---|

| DGUV Regulation 101-011 (PDF, German) |

| DGUV Regulation 108-007 (PDF, German) |

Products

Further Guidelines & Info Pages

modified eCommerce Shopsoftware © 2009-2026

Code & Implementation: Rehm Webdesign