Load Securing & Cargo Net Guidelines

Table of Contents

1.

Load securing nets are used to secure loads on or in vehicles against falling out or slipping during the journey. This serves on the one hand to protect the load itself, but above all to protect the driver and other road users.

If the load is not properly secured, the inertia force can cause the loaded goods to move forwards or backwards when braking or accelerating or when cornering. Whenever the mass force acts more strongly than the weight force and the frictional force, which push the goods towards the ground and hold them in place, the load must be additionally secured with the aid of load securing equipment. How exactly the load is secured is regulated by law â and is discussed in more detail below.

Section §22 paragraph 1 of the German Road Traffic Regulations (StVO) states that loads in motor vehicles must be stowed and secured in such a way that they cannot slip, fall over or drop during emergency braking or sudden evasive movements. The recognized rules of technology must be observed.

Suitable measures are specified in guideline no. 2700 of the Association of German Engineers (VDI Guideline 2700: "Load securing on road vehicles") and can be regarded as "recognized rules of technology". Sheet 3.3 in particular describes the suitability of nets for load securing.

For vehicles with a total weight of over 3500 kg, the European standard EN 12195-2 "Load securing equipment on road vehicles - Part 2: Lashing straps made of man-made fibers" also applies. This standard describes the use of lashing straps for load securing and defines their requirements.

These guidelines and regulations are binding for both commercial and private transport.

According to §23 "Other obligations of vehicle drivers" of the Road Traffic Regulations, the loader, owner and above all the driver of a vehicle are responsible for its road safety and thus also for securing the load. The driver of the vehicle must ensure that his vision and hearing are not impaired by the load. Furthermore, he must ensure that the traffic safety of the vehicle is not impaired by the load.

If the loading of the vehicle or the securing of the load is carried out by another person, the driver, as the person primarily responsible, must supervise the measures for securing the load or check and accept them before driving off.

A basic distinction is made between force-fit load securing and form-fit load securing:

Force-fit load securing is achieved when a frictional connection is created between the load and the loading surface and the friction is increased. This can be achieved, for example, by lashing down using tension belts. If a lashing is lashed down by hand and ratchet, a certain pretensioning force is created which presses the load onto the surface and increases the frictional force there.

Form-fit load securing, on the other hand, is achieved when the load is arranged flush and without gaps or is lashed at an angle. In the case of partial loads, tight fit can be achieved by clamping bars and sliding partitions, but also by using nets.

Force-fitting load securing and form-fit load securing can be used in combination. In this case, elements of the form-fit load securing complement the force-fit load securing.

5.1

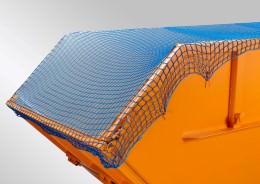

Cover nets are used to secure loose goods on open loading areas, containers or bins and provide protection against ejection or to secure objects in a vertical direction. They may be used as an aid for securing loose, lightweight items. Cover nets which are stretched over an open loading area are not to be regarded as form-fit load securing. However, a cover net can be used in combined load securing to create an additional tight fit for a load that has been secured by a frictional connection.

This type of net is usually made of knitted mesh material (e.g. polypropylene or polyethylene fibers).

This type of net is usually made of knitted mesh material (e.g. polypropylene or polyethylene fibers).

Covering nets are usually hung in hooks that are firmly attached to the loading area. Alternatively, the installation can also be carried out with a circumferential tension cord. This is simply pulled over the corners or existing attachment points.

5.2

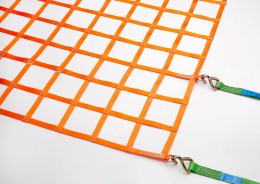

Cover nets can also be used as an aid for lashing down cargo. In this case, the net is combined with other fastening devices such as tension belts or similar. Webbing nets can also be used as lashing nets.

The load can also be bundled into larger load units with the help of such a net, which is then in turn fixed with force-fitting load securing.

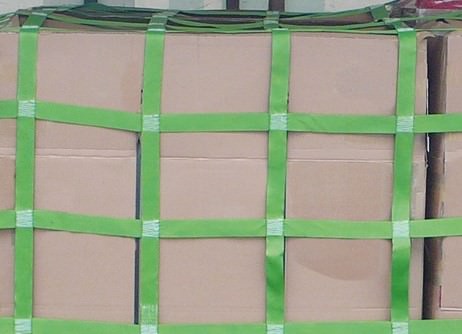

Webbing nets combine force-fit and form-fit load securing. The net over the load creates a tight fit, which is lashed diagonally or at an angle. At the same time, the net is lashed down using tension belts. The belt strap net itself is made of webbing material, which is also used to manufacture lashing straps.

The use of anti-slip mats or other friction-enhancing aids is recommended. The webbing nets must comply with the requirements of VDI Guideline 2700 and EN 12195-2 .

Assembly is carried out by means of a fixed number of tensioning straps, which are hooked into predefined points on the edge of the net. These are suitably designed in relation to the size and thickness of the net.

5.4

Vertically tensioned separating nets can be used for form-fit load securing. For this purpose, they are tensioned directly against the cargo, thus restricting the horizontal freedom of movement of the cargo or cargo units. Partition nets can also be used for simple segmentation of the cargo space.

This type of net is usually made of webbing. This must meet the requirements of EN 12195-2 . Separation nets are installed on the connecting elements provided for this purpose in the vehicle body (e.g. on fastening rails).

5.5

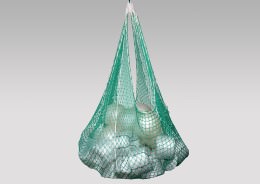

Furthermore, nets can also be used directly for transporting goods. Similar to big bags, they act as bags for loose goods. Nets used as transport or loading aids are not subject to the load securing guidelines in the sense of VDI 2700 or the German Road Traffic Regulations (StVO), as strictly speaking they do not serve to secure loads during movement in road traffic.

5.5

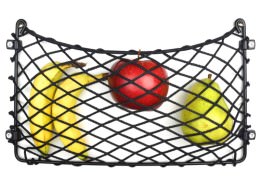

With the help of luggage nets, small parts can be secured in bundles. They are installed in the passenger compartment of a car using a mounting device provided by the manufacturer. However, the load-bearing capacity of such constructions limits the use of these nets to small and light parts.

Most often, luggage nets are made of polypropylene or polyethylene fibers.

6.

Load securing nets and net accessories must be stored appropriately between two periods of use.

To ensure adequate storage, it needs:

- a dry environment

- protection from UV radiation

- protection from heat

- protection from aggressive substances (e.g. acids, alkalis, solvents, oils)

When not in use, storage in the vehicle interior is recommended.

During operation, the network must be visually inspected at regular intervals. In addition, it must be inspected at least once a year by a qualified person.

Nets with visible damage (torn mesh, damaged edge rope) must not be used any further. A damaged net can be repaired by the manufacturer of the net. In this case, proof must be provided that the net meets the required strength values.

There is no fixed expiration date for lashing straps and the like. The expiration date is reached at the latest when the information on the label is no longer legible. In the event of any defects, the lashing equipment must be withdrawn from circulation before this point.

Products

© 2026 Schutznetze24 GmbH • All Rights Reserved

modified eCommerce Shopsoftware © 2009-2026

modified eCommerce Shopsoftware © 2009-2026

Design: construktiv GmbH

Code & Implementation: Rehm Webdesign

Code & Implementation: Rehm Webdesign