Lashing Straps & Tension Belts

A step on the brakes, a jerky evasive maneuver or even just a steep curve: In road traffic, not everything always runs smoothly, predictably and straight ahead. This makes it all the more important that everyone involved is properly secured - this applies to people, animals and objects of all kinds. Especially at high speeds, sudden emergency braking, abrupt steering movements and the like - but also quite simply in everyday driving - unsecured loads can become a serious problem and quickly pose a danger to yourself and other road users.

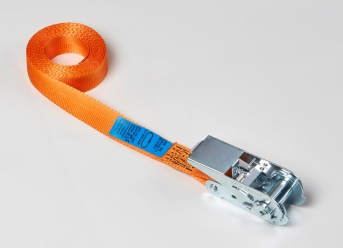

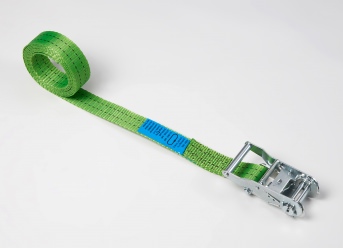

Tension straps are true all-purpose weapons for securing loads. The space-saving webbing straps secure objects of all kinds by means of lashing force and, thanks to their high load-bearing capacity, are ideal for use in road traffic. Tension belts or lashing straps are available in numerous different designs: They are available in various widths and lengths as one-piece and two-piece lashing straps, and the tensile force also varies from model to model. Depending on the intended use, different types of closure and connection are suitable: There are tension belts with clamp locks and ratchets - here, for example, a distinction is made between compression ratchets and tension ratchets - as well as two-piece tension belts with different end fittings, for example with triangle hooks, pointed hooks or frame hooks.

according to DIN 60060 & EN 12195

Max. Tensile Force: 400 daN

one-piece load restraint assembly

according to DIN 60060 & EN 12195

Max. Tensile Force: 800 daN

one-piece load restraint assembly

according to DIN 60060 & EN 12195

Max. Tensile Force: 500 daN

two-piece load restraint assembly

according to DIN 60060 & EN 12195

Max. Tensile Force: 2000 daN

one-piece load restraint assembly with light ratchet

according to DIN 60060 & EN 12195

Max. Tensile Force: 1000 daN

two-piece load restraint assembly with light ratchet

according to DIN 60060 & EN 12195

Max. Tensile Force: 4000 daN

one-piece load restraint assembly

according to DIN 60060 & EN 12195

Max. Tensile Force: 3000 daN

one-piece load restraint assembly with heavy ratchet

according to DIN 60060 & EN 12195

Max. Tensile Force: 1500 daN

two-piece load restraint assembly with heavy ratchet

according to DIN 60060 & EN 12195

Max. Tensile Force: 2000 daN

two-piece load restraint assembly with double hooks

according to DIN 60060 & EN 12195

Max. Tensile Force: 2000 daN

two-piece load restraint assembly with single hooks

Tension Belts In Use: Legal Basis

Since appropriate load securing in road traffic is essential not only for one's own sense of safety but also for the protection of other road users, the use of tension belts, lashing straps and the like is prescribed by law. According to Section 22 of the German Road Traffic Regulations (StVO), it is the legal duty of every road user to ensure that the transported load is properly secured with the help of lashing straps.

In concrete terms, this means that transported goods in and on the vehicle - whether a car, van or truck - must not slip, slide, roll or even fall off during the journey. The same applies to objects stored on a trailer. Anyone who fails to secure their load at all or inadequately, or who uses unprofessional aids, is in breach of the German Road Traffic Regulations (StVO) and must expect criminal consequences in the event of damage or inspection.

The standards EN 12195-2 and DIN 60060 ensure the proper and largely uniform securing of transport goods by means of tensioning belts. Depending on the area of application, they regulate how a tensioning belt must be designed and processed, and establish rules for labeling and use. According to ENnbsp;12195-2, for example, professional tension belts must be provided with a label containing the following information:

- ■manufacturer's data

- ■test number and certificate

- ■manual force

- ■lashing force

- ■permissible lashing force

- ■material

- ■maximum elongation

- ■year of manufacture

- ■traceability code

- ■length specification

- ■conformity to standard

Whenever a tensioning strap or lashing strap is used for load securing - in road transport, in logistics as well as in industry - it is important to check whether the webbing and ratchet or clamping buckle are free of defects before use. As soon as you notice wear, the lashing strap has reached its so-called discard age and it is time for a new one.

Tension Belts Made To Measure At Safetynet365

Our dimensionally accurate lashing straps are made of polyester, impregnated and equipped with abrasion resistance. Galvanized steel and a stretched strap make the robust lashing straps a reliable aid in the field of load securing: hard-wearing and durable. In the production of our single-color lashing straps, we use only high-quality materials and always ensure that all our products comply with the applicable standards for lashing straps and are equipped with a GS test certificate.

In our online store you will find custom-made lashing straps in various designs. By determining the length of the lashing strap yourself, you can optimally adapt the product to your area of application. The custom-made lashing straps are each available in a standardized width of 25 mm, 35 mm and 50 mm and can be purchased in one or two parts. Depending on the model, the permissible tensile force is between 400 daN and 4,000 daN.

In addition to ratchet straps, which are lashed with a light or heavy ratchet, there is also a tension belt with a clamp lock. The two-piece lashing straps are connected with a single or double hook, depending on the model, and are suitable both for strapping and for securing loads in a U-shape, whereas the one-piece lashing straps without hooks are specifically for strapping.

Properties of our tension belts made to measure:

- ✓made to measure: individual length

- ✓belt straps made of impregnated polyester

- ✓tensioning elements and end fittings made of galvanized steel

- ✓high-quality workmanship

- ✓ideal for load securing: road transport, logistics, industry

Order tension belts made to measure in various designs:

- ■Length: freely selectable

- ■Belt width: 25 mm, 35 mm, 50 mm

- ■Tensile force: 400 daN, 500 daN, 1,000 daN, 1,500 daN, 2,000 daN, 3,000 daN, 4,000 daN

- ■Design: 1-piece or 2-piece

- ■Tensioning element: light ratchet, heavy ratchet or clamp fastener

- ■Fitting: single hook or double hook

Supplement Tension Belts: Anti-slip Mats, Nets & Co.

With the help of tension belts, you can tie down your load and thus properly secure it in and on the vehicle as well as on the trailer. Various ratchets, such as compression, tension and long-lever ratchets, as well as clamp locks and hooks, ensure that the load is firmly enclosed by the tensioning strap or strapped to the means of transport. The ratchets or locks make the small, easily stowable lashing straps a popular aid for securing loads.

Depending on the load and its use, however, it can happen that tension belts alone - despite their secure closure and reliable system - are not sufficient to adequately store and secure the sometimes heavy or bulky load. In such cases, there are various ways in which load securing can be extended: for example, with the aid of lashing chains, anti-slip mats or nets. While lashing chains work in a similar way to lashing belts, anti-slip mats are placed underneath due to their anti-slip effect in order to prevent objects from sliding away or slipping - especially on smooth or sloping surfaces. Nets, in turn, can catch flying and falling objects or, as belt strap cargo nets, prevent heavy goods from slipping. If the load can be secured well with lashing straps, but has sharp edges or is made of soft materials that can easily be damaged, additional edge protection for lashing straps is recommended. This is placed underneath and connected to the lashing strap so as not to damage cardboard and the like.

Whether additional equipment is needed to secure your cargo in addition to lashing straps depends on various factors: the nature of the cargo and the loading area, the load-bearing capacity and size of the belt systems, and last but not least, to a certain extent, your personal sense of safety. So whenever you have any doubts about whether the strapped belts are sufficient to effectively secure transported goods, it is advisable to take further measures. This way, you and your fellow human beings will get through road traffic safely - and get your cargo from point A to point B without loss or wear.

If you have any questions about products and use, we will be happy to advise you. Simply get in touch with us.

modified eCommerce Shopsoftware © 2009-2026

Code & Implementation: Rehm Webdesign