Main pageSafety Net Guidelines & Standards

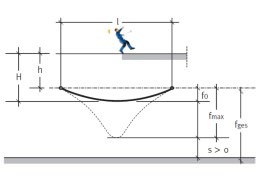

Safety Net Guidelines & Standards

Construction Netting Guidelines

Guidelines For Other Safety Nets

Contact Us

- Schutznetze24 GmbH

Weyerberg 5

35614 Aßlar-Berghausen

GERMANY - +49 6443 - 436 96 40

![]() +49 6443 - 436 96 40

+49 6443 - 436 96 40- +49 6443 - 436 96 70

- office@safetynet365.com

Information

- Net Material Overview

- Assembly Instructions

- Building-Site Safety Netting Guidelines

- EN 1263-1 Safety Net Calculator

- FAQs

- Customer Images

- List of References

Useful Links

Bestseller

Custom-Made Netting

Nets for Home & Garden

Construction & Industry

Certifications

Awards

Accepted Payments

© 2026 Schutznetze24 GmbH • All Rights Reserved

modified eCommerce Shopsoftware © 2009-2026

modified eCommerce Shopsoftware © 2009-2026

Design: construktiv GmbH

Code & Implementation: Rehm Webdesign

Code & Implementation: Rehm Webdesign

safetynet365.com

- Customisation

- Construction

- Industry

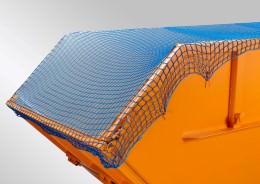

- Load Securing

- Home & Garden

- Sport

- Information

- Contact

Contact Us

Monday - Thursday: 8:00 to 17:00

Friday: 8:00 to 12:00

Pickups and visits only with previous notice.

Friday: 8:00 to 12:00

Pickups and visits only with previous notice.

+49 6443 - 436 96 70

Schutznetze24 GmbH

Weyerberg 535614Aßlar-BerghausenHessenDE

+49 6443 4369640office@safetynet365.comhttps://safetynet365.com/templates/tpl_modified/img/logo/logo_head_en@2x.pnghttps://safetynet365.com/templates/tpl_modified/img/logo/logo_head_en@2x.png