Working Platform Net Guidelines

With regard to the handling of safety nets as well as their maintenance, repair and replacement, the requirements of DGUV regulation 101-011 apply.

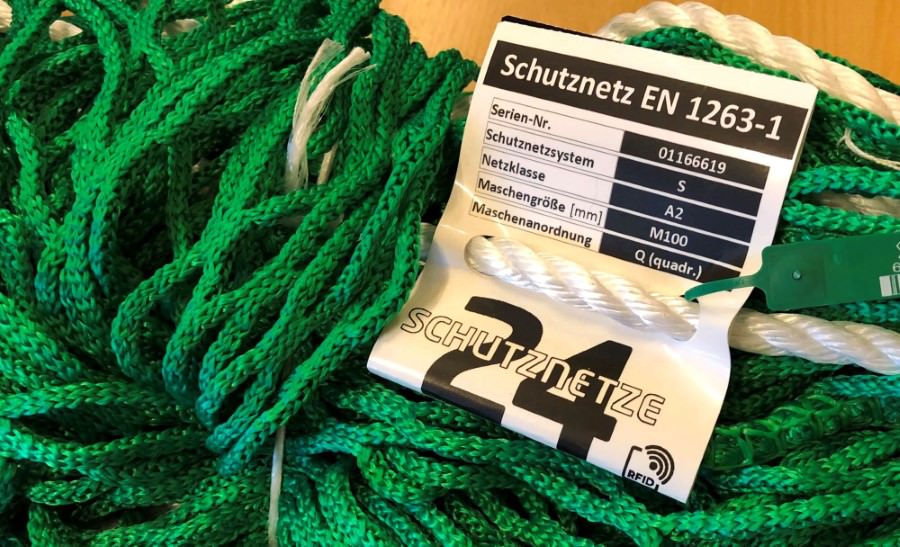

- Manufacturer, supplier or importer

- Designation according to EN 1263-1

- Article designation (incl. net class, mesh direction, mesh size and net size)

- Month and year of manufacture

- Minimum energy absorption capacity of the test mesh. This already takes into account a loss of strength due to aging over a period of 12 months, as well as a general safety factor.

- Test number of the testing institution that certified the net

- Basic knowledge of legal regulations and occupational safety regulations of the accident insurance institutions,

- sufficient practical work experience in the installation of safety nets,

- knowledge of work platform nets and their load-bearing behavior and interaction with the structure (construction),

- knowledge of possible hazards and how to eliminate them (e.g. falling, falling objects, lifting, carrying and transporting loads, hazardous working materials), and

- knowledge of the plan for assembly, modification and dismantling as well as the plan for use and the instructions for assembly and use for the respective work platform net.

- Explanation of the plan for erecting, modifying, or dismantling the work platform network in question,

- instructions for safe assembly, modification or dismantling of the relevant work platform network (including transport of materials),

- Designation of preventive measures against the danger of persons falling and objects falling down,

- Information on safety precautions in the event that weather conditions change in such a way that the safety of the relevant work platform net and the persons concerned could be impaired, and

- Information on permissible loads, taking into account traffic (construction operations) and material storage.

| You can find a sample assembly instruction at the following link: Sample assembly instructions (PDF, German) |

- The inclination of the net construction is not more than 22,5°

- The net construction is not lower than 1.50 m below the lower edge of the structure to be erected

- The structure and the anchor points can safely withstand the expected load during operation. Suitable anchor points can be ring anchors, steel structures, reinforced concrete girders or glulam trusses, for example.

- The safety net used complies with EN 1263-1 and has a maximum mesh size of 45 mm

- The safety net used has a valid strength certificate in accordance with DGUV regulation 101-011

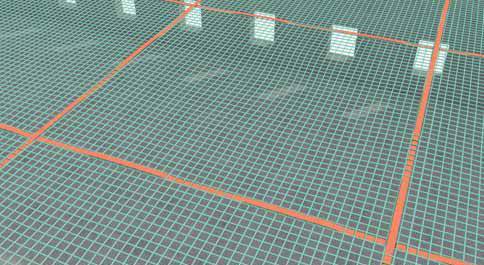

- The crossbar belts can be threaded through the net in a maximum pattern of 2.00 x 2.00 m

- The net construction can be anchored all around in a distance of max. 50 cm

- When the net is used, a maximum load of 6 kN is transferred to the supporting structure

| 1. | The net must not be used as a working platform until final inspection and acceptance. During the assembly itself, the employees performing the work must be secured against falling. |

| 2. | Where necessary, the outer edges of the work platform net must be provided with effective fall protection (e.g. roof edge protection). |

| 3. | The safety nets, tension belts and other work equipment to be used must be checked for damage. Damaged nets or accessories (e.g. damaged meshes or a torn tensioning strap) must not be used any further and must be replaced. |

| 4. | Do not use any working methods or equipment that may cause damage to the net during installation (e.g. welding, cutting, sharp edges). |

| Assembly Procedure for the Erection of Work Platform Nets | ||||

| 1. Mount the Safety Net First, the safety net is mounted inside the supporting structure. Make sure that the inclination of the subsequent working platform does not exceed 22.5°. Fastening to the edge is done with tension belts at a maximum distance of 50 cm. These are tied around the supporting structure and the net. The anchorage forces are dimensioned analogously to DGUV regulation 101-011 with 6 kN at each anchorage point. The tension belts used should have a permissible tensile force of 2500 daN.

| |||

| 2. Pull In the Supporting Traverse Straps Several tensioning belts are threaded through the net in such a way that they are positioned in a pattern of no more than 2.00 x 2.00 m from each other and have a distance of no more than 2.00 m from the edge. For threading, the open end of the tensioning belt is simply passed through the meshes of the net. The puncture takes place after a maximum of 10 meshes in each case. The tensioning belts used should have a maximum tensile force of 1500 daN.

| |||

| 3. Pretension of Net Construction The supporting traverse belts are tensioned by hand. Horizontal loads of at least 2200 N per anchor point are to be expected. The tensioning belts are first tightened so that the sag of the net does not exceed 30 cm when loaded with a standing person. This value applies to the most unfavorable point in the net, i.e. usually within a tensioning strap grid in the middle part of the net construction. | |||

| 4. Retensioning After 24 Hours Due to the settling behavior of the materials and the overall construction, the net sag may change over the first 24 hours. After one day, the tensioning straps should be tightened again so that the sag of the net does not exceed 30 cm again when loaded with a standing person. The belts should be checked and retightened as required during the further course of use. | |||

Once the net manufacturer has satisfied himself of the proper condition of the construction, he may hand it over to the user.

| A sample test and handover protocol can be found at the following link: Sample test protocol for work platform networks (PDF, German) |

| A sample checklist for the user can be found at the following link: Sample checklist for the work platform network user (PDF, German) |

If defects are found in safety nets or net accessories, these parts may only continue to be used if it has been determined by a competent person that safety is not impaired by the defects.

- Damaged edge rope

- Torn mesh (if more than 2 adjacent mesh legs in the net are damaged, the net must be replaced or repaired immediately)

- Damage to the supporting structure

- Damaged fasteners

- in a dry environment,

- protected from UV radiation,

- protected from heat, and

- not stored in contact with aggressive substances (e.g. acids, alkalis, solvents, oils).

Products

Further Guidelines & Info Pages

modified eCommerce Shopsoftware © 2009-2026

Code & Implementation: Rehm Webdesign