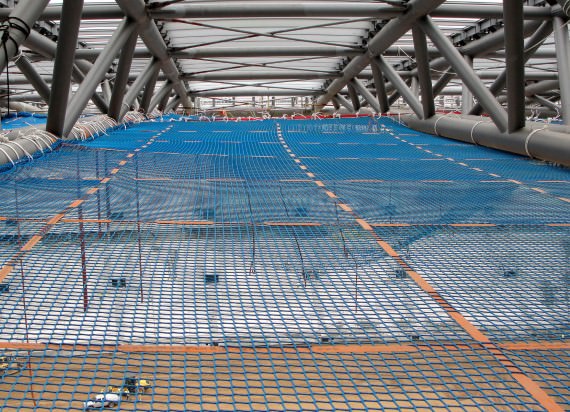

A safety net, also known as a fall-arrest net, fall safety net or construction net, is a horizontally tensioned protective net with an edge rope drawn into the edge meshes. The nets are used to catch people when working under hall roofs and in bridge construction, among other things. Fall safety nets are used when direct prevention of a fall is unavoidable. In contrast to rope anchors, the freedom of movement remains fully intact. It is a collective safety device for all work and transport operations in the secured area. Falling persons are caught more softly than in the case of roping devices.

The standardised designation for a horizontally tensioned safety net with edge rope is "Safety Net EN 1263-1 System S". Within this category, a further distinction is made between 4 net classes depending on the minimum breaking energy, which must meet the following requirements:

| Net Class | Maximum Mesh Size | Required Minimum Energy Absorption

When New |

|---|

| A1 | 60 mm | 4.14 kJ |

| A2 | 100 mm | 4.14 kJ |

| B1 | 60 mm | 7.92 kJ |

| B2 | 100 mm | 7.92 kJ |

When testing static energy absorption, a test net with a size of 3.00 x 3.00 m must cover at least the aging of one year with a safety factor of 1.5. The safety nets available from us have a larger reserve than required and therefore offer the greatest possible safety (see table).

| Net Class | Mesh Size | Energy Absorption | Max. Tensile Strength of a Mesh |

|---|

| A1 | 60 mm | approx. 6.1 kJ | approx. 3200 N |

| A2 | 100 mm | approx. 4.8 kJ | approx. 3200 N |

| B1 | 45 mm | approx. 9.0 kJ | approx. 3200 N |

Fall protection is mandatory for work where there is a risk of falling. The legal framework for occupational safety is provided by the Occupational Safety Act. This in turn is governed by accident prevention regulations. The use of safety nets is specified in DGUV regulation no. 101-011. The product standard for safety nets is EN 1263-1.

Only safety nets that comply with this standard are approved products within the meaning of DGUV regulation 101-011 and thus also approved for fall protection within the meaning of the Occupational Safety and Health Act and accident prevention regulations.

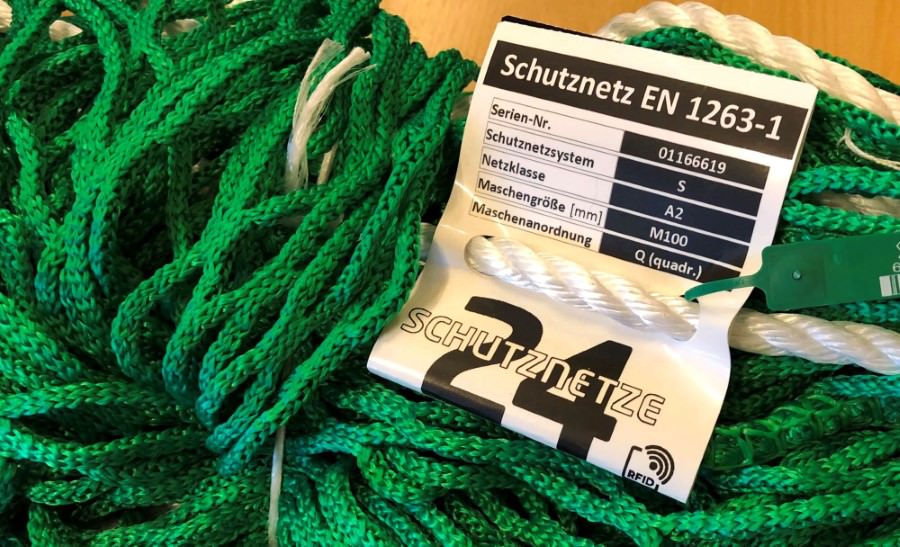

Each safety net must be marked in accordance with EN 1263-1. The following information must be clearly and permanently affixed to the safety net:

- Manufacturer, supplier or importer

- Designation according to EN 1263-1

- Article designation (incl. net class, mesh direction, mesh size and net size)

- Month and year of manufacture

- Minimum energy absorption capacity of the test mesh. This already takes into account a loss of strength due to aging over a period of 12 months, as well as a general safety factor.

- Test number of the testing institution that certified the net

For the installation of safety nets, the executing force must have the manufacturer's instructions for use and the contractor's installation instructions available according to DGUV regulation/nbsp;101-011.

The requirements and measures described under the following points "Authorized Persons and Responsibilities", "Assembly Instructions" and "Repair, Maintenance and Replacement" apply as instructions for the use of safety nets in accordance with DGUV regulation 101-011.

In addition, the responsible contractor must prepare written assembly instructions tailored to the respective application. The written form can be dispensed with if no special safety-related information is required for the respective installation. The instructions for use and, if applicable, the written installation instructions must be available at the point of use and must be observed. The documents should contain information on the net size, the required accessories, the selection of suspension points and the installation procedure.

With the links below you will find a leaflet of the BG Bau, the published regulation of the DGUV as well as further downloads on the subject of safety nets:

The installation of safety nets must be directed by a technically suitable supervisor and supervised by a competent person. The responsible persons must ensure that the work is carried out in accordance with the regulations.

A person is considered "competent" if, for example, he or she has successfully participated in the seminar "Training of net fitters for the installation of protective and work platform nets" in accordance with DGUV principle 301-004.

The person also considered to be a skilled worker if she has

- Basic knowledge of legal regulations and occupational safety regulations of the accident insurance institutions,

- sufficient practical work experience in the installation of safety nets,

- knowledge of safety nets and their interaction with the supporting structures,

- Knowledge of potential hazards and how to eliminate them (e.g., falling, falling objects, lifting, carrying and transporting loads, hazardous materials), and

- Knowledge of the plan for assembly, disassembly and use and the assembly and use instructions for the respective safety net.

A plan must be drawn up for the installation, modification, dismantling and use of the safety net. These instructions for use can be used for this purpose. If necessary, it should be supplemented with special instructions for use.

If special safety-related information is required for installation work with protective netting, the contractor must prepare written installation instructions containing all the necessary safety-related information, including the specifications made by the planner and the coordinator in accordance with the Construction Site Ordinance. The assembly instructions must be available at the assembly site and to the supervisor.

An installation instruction should contain information about the following points:

- net sizes

- the necessary accessories

- the choice of suspension points

- the installation procedure

- accessibility of components

- required devices and installation aids

- openings

- installation points

- set-up and use of workplaces and traffic routes for installation of the safety nets

- fall protection devices

- suitable anchor points when using PPE against falls from a height.

Every contractor who uses a safety net to protect his own employees or temporary workers against falls from a height is responsible for ensuring that the safety net is in proper working order. Before the safety net is put into operation for the first time, it must be checked to ensure that it is functioning safely. This check can be facilitated by the company's own risk assessment, plan for use or instructions for use.

Objects that have fallen into the net must be removed immediately if persons can be injured by them when they hit the net or if the load-bearing capacity of the net is impaired. If safety nets or net accessories are stressed by catching a person or an object, they may only be used again with the approval of a competent person.

Ropes must be secured against untwisting. Damage during handling, especially from sharp edges, should be avoided.

The dimensions of a safety net may only be changed by the manufacturer. It must be re-marked in the event of a change by the manufacturer. A safety net whose dimensions have not been changed by the manufacturer automatically loses its approval according to EN 1263-1.

The area of a horizontally tensioned system S safety net must be at least 35 m² according to EN 1263-1. The length of the short side must be at least 5.00 m. If these minimum dimensions are not complied with, a safety net is considered to be a so-called "small-sized safety net".

According to DGUV regulation 101-011, such a net may also be used as a safety net if the following parameters are observed:

- If the installation width is less than 5.00 m, a maximum fall height of 1.50 m must be maintained.

- If the installation width is less than 3.00 m, a maximum fall height of 1.00 m must be maintained.

- If the installation width is less than 2.00 m, a maximum fall height of 0.50 m must be maintained.

In addition, the mesh size of this net must not exceed 60 mm.

| The conformity and maximum possible fall height can be easily determined with the help of our

Safety Net Calculator |

The area of a small-format safety net in accordance with DGUV regulation 101-011 must be at least 2.00 m². The length of the shorter side must be at least 1.00 m. The width of the net must exceed the distance between the opposite suspension points by at least 10 cm, so that the net is installed with a sag (slack installation).

If an existing safety net is larger than the area to be covered, it may be gathered or rolled up in the edge area up to one meter per side. For example, a safety net with dimensions of 6.00 x 10.00 m can be stretched into an opening of 4.00 x 8.00 m.

When assembling the net, it is important to ensure that the entire gathers are anchored, including the edge of the net and the edge rope.

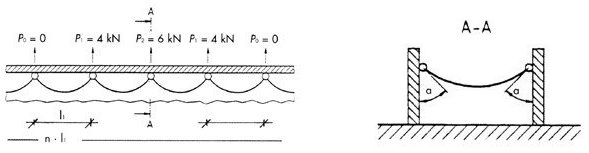

Construction nets must be attached to load-bearing points. Each suspension point shall have been designed for a characteristic load of at least 6 kN at an angle of 45°. Three characteristic loads of 4 kN, 6 kN and 4 kN at the most unfavorable point shall be considered for the design of the structural members. The suspension points must not be more than 2.50 m apart.

The forces that occur must be able to be safely absorbed and transmitted by the suspension points and structural parts.

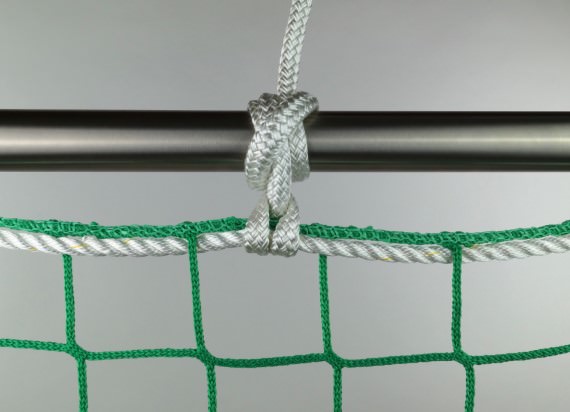

Safety nets are suspended using suspension ropes, safety snap hooks, shackles, net thimble loops or safety net thimble hooks. In the case of single-strand suspension with ropes, the breaking force of the suspension rope must be at least 30 kN, in the case of double-strand suspension, the breaking force must be at least 15 kN. For attachment methods other than suspension ropes, a safety factor of 2 must be used.

The distance between the attachment points must not exceed 2.50 m. For small-format safety nets, the maximum distance between the attachment points is reduced analogously to the net size (see table below).

| Net Size | Max. Falling Height | Distance Between

Suspension Points | Min. Clearance Under Net |

|---|

| span width 1.00 m to < 2.00 m | 0.50 m | ≤ 1.00 m | 1.50 m |

| span width 2.00 m to < 3.00 m | 1.00 m | ≤ 1.50 m | 2.00 m |

| span width 3.00 m to < 5.00 m | 1.50 m | ≤ 2.00 m | 2.50 m |

span width ≥ 5.00 m and

net area < 35 m² | 1.50 m | ≤ 2.00 m | 2.50 m |

span width ≥ 5.00 m and

net area ≥ 35 m² | 6.00 m | ≤ 2.50 m | depends on net size and falling height |

| The conformity and maximum possible fall height can be easily determined with the help of our

Safety Net Calculator |

| Installation Variants |

![Safety Net Installation with Ropes]() | Installation with Looped Suspension Ropes Suspension ropes with a spliced loop are used to achieve a standard-compliant single-strand suspension. The loop side is attached to the net. Non-detachable knots must be used or the knots must be secured against unintentional detachment. A recommended knot is a clove hitch. |

![Safety Net Installation with Ropes]() | Installation with Ropes As an alternative to point attachment with suspension ropes, endless rope can also be used for wrapping and attachment. The rope must have a minimum breaking strength of at least 30 kN for single-strand suspension or 15 kN for double-strand suspension. During installation, non-detachable knots must be used or the knots must be secured against unintentional detachment. |

![Safety Net Installation with Hooks]() | Installation with Snap Hooks Safety snap hooks are flexible in use. They can be used to provide safety nets with load-bearing suspension points at variable locations. The snap hooks used should have a load capacity of at least 6 kN. |

![Safety Net Installation with Anchors]() | Installation with Heavy-duty Anchors In the case of a concrete support structure, heavy-duty anchors and hooks can be used as a substructure. These, in turn, can be combined with safety snap hooks by means of which the nets can be hooked in. |

![Safety Net Installation with Thimble Hooks]() | Installation with Thimble Hooks Thimble hooks can be used to provide safety nets with load-bearing suspension points at variable locations. The thimble hooks can then be hooked or suspended in the same way as thimble loops. |

![Safety Net Installation with Tension Belts]() | Installation with Tension Belts Safety nets can be attached to the substructure using lashing straps. By threading lashing straps through the safety net with a maximum grid of 2.00 x 2.00 m, it is also possible to create walkable work platform nets (see also our working platform safety net guidelines). |

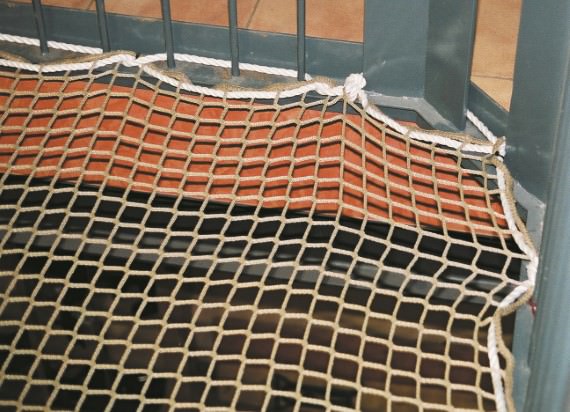

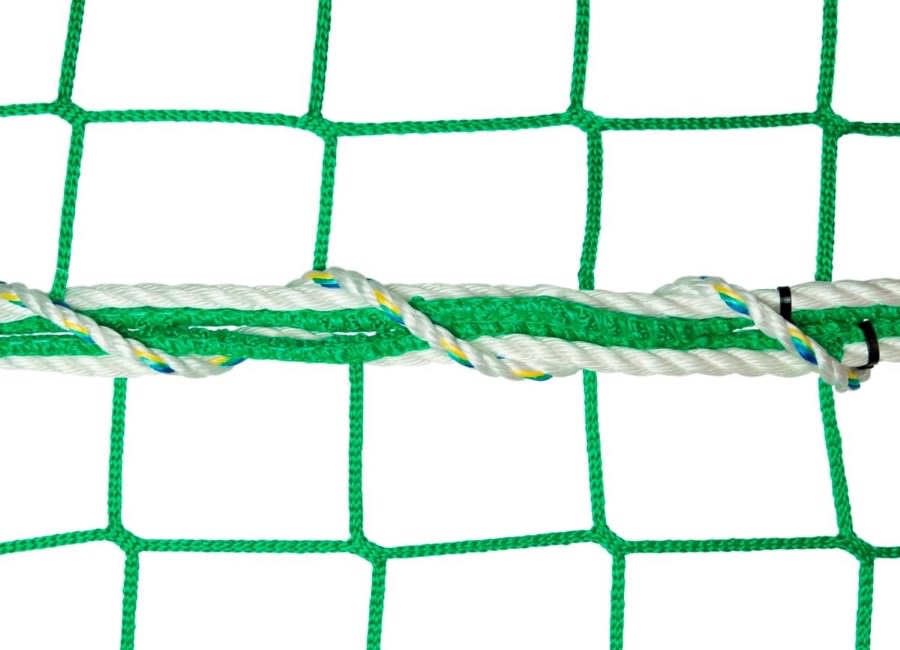

If several construction nets are connected to each other, coupling ropes must be used in such a way that there are no gaps of more than 100 mm at the connection point and the safety nets cannot shift more than 100 mm against each other. The coupling rope is threaded through the edge meshes of the two safety nets to be connected. Coupling ropes according to EN 1263-1 must have a breaking strength of at least 7.5 kN.

Safety nets can also be connected without a coupling rope by overlapping the nets. In this case, the overlap of the net edges must be at least 2.00 m in accordance with EN 1263.

The net composite is to be regarded as one continuous net surface when coupled. As soon as coupling ropes are used or a safety net area is created by means of overlapping, it must be ensured that the clearance under the safety net and the specified fall height of the coupled or overlapped net areas comply with the requirements.

The horizontal distance between the net and the edge of the fall must not exceed 0.30 m. This also applies, for example, to the suspension of nets from central or intermediate girders in hall construction.

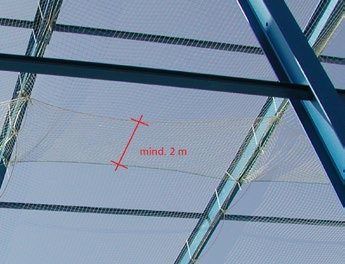

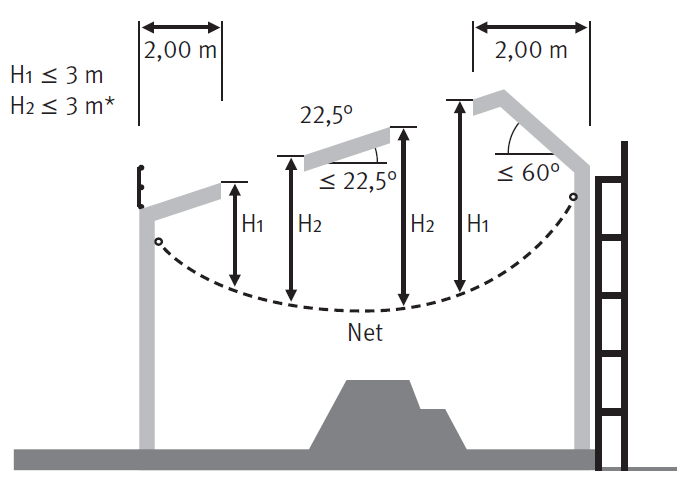

A safety net must be suspended as close as possible below the workplace to be secured. The fall height must not exceed 6.00 m. In the peripheral area, up to a horizontal distance of 2.00 m from the suspension point, the permissible fall height must not exceed 3.00 m. The fall height is the difference between the edge of the fall and the height of impact on the net.

In the case of small-format safety nets smaller than 35 m², lower values must be observed for the fall height, the distance between the suspension points and the clearance under the safety net, depending on the width of the net, in accordance with DGUV regulation 101-011 (see table below).

| Net Size | Max. Falling Height | Distance Between

Suspension Points | Min. Clearance Under Net |

|---|

| span width 1.00 m to < 2.00 m | 0.50 m | ≤ 1.00 m | 1.50 m |

| span width 2.00 m to < 3.00 m | 1.00 m | ≤ 1.50 m | 2.00 m |

| span width 3.00 m to < 5.00 m | 1.50 m | ≤ 2.00 m | 2.50 m |

span width ≥ 5.00 m and

net area < 35 m² | 1.50 m | ≤ 2.00 m | 2.50 m |

span width ≥ 5.00 m and

net area ≥ 35 m² | 6.00 m | ≤ 2.50 m | depends on net size and falling height |

| The conformity and maximum possible fall height can be easily determined with the help of our

Safety Net Calculator |

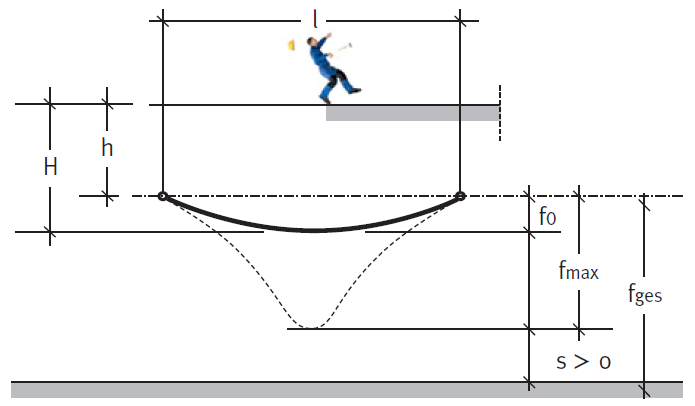

A fall safety net must be suspended in such a way that persons cannot touch the ground, hit fixed or moving objects or injure other persons in traffic areas during the fall arrest process. When calculating the clearance, not only the deformation under load but also the sag in the unloaded state must be taken into account. In addition, a safety clearance of s > 0 must be kept free for any traffic routes or fixtures.

| l | = | span width of safety net |

| h | = | perpendicular distance between the building edge and the suspension point of the safety net |

| H | = | perpendicular distance between the building edge and the impact surface in the safety net |

| f0 | = | deformation due to dead load of the safety net |

| fmax | = | largest deformation due to dead load and dynamic load |

| s | = | safety distance for possible traffic routes or fixtures |

| fges | = | clearance height resulting from maximum deformation due to dead load and dynamic load and safety distance for possible traffic routes or fixtures |

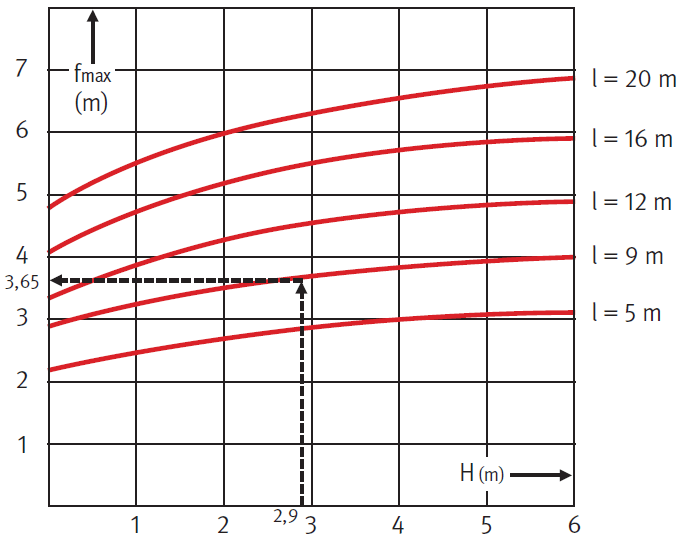

The net deformations due to dead load and dynamic load may be determined approximately according to the curves shown below.

| With our Safety Net Calculator, the net sag can be easily calculated depending on the net size and falling height. |

The net sag can be reduced by installing supporting ropes. Truss ropes are pulled into a safety net parallel to the edge to reduce the net sag and must be connected to the edge ropes. An additional reduction of the sag can be achieved by fastening with suspension ropes of the truss rope towards the top.

By reducing the net sag compared to the requirements from the previous values, fall-arrest nets can already be used with a clearance height of more than 3.00 m if

- the length of the shortest side of the safety net does not exceed 7.50 m

- the net sag in the middle of the unloaded safety net is no more than 3.5% of the shortest side (approx. 0.26 m for a net width of 7.50 m) of the safety net and

- the fall height from the fall edge of the respective workplace to the possible impact surface of the safety net is not more than 2.50 m perpendicular.

After the installation of a safetny net, the responsible contractor must arrange for an inspection to determine its proper condition. The inspection may only be carried out by a competent person (e.g. the supervisor).

The results of the test must be documented in the form of a test report and should be kept for at least three months beyond the service life of the safety net.

Once the safety net manufacturer has satisfied himself of the proper condition of the safety net, he may hand it over to the user.

Defects in work equipment, facilities, work procedures or work processes that could result in hazards for the employee must be reported immediately to the supervisor and may not be used further without approval.

If defects are found in safety nets or net accessories, these parts may only continue to be used if it has been determined by a competent person that safety is not impaired by the defects.

Examples of safety-related defects are:

- damaged edge rope

- torn mesh (if more than 2 adjacent mesh legs in the net are damaged, the net must be replaced or repaired immediately)

- damage to the supporting structure

- damaged fasteners

Damaged safety nets and net accessories may only be repaired by the manufacturer or persons designated by him. Only material with the same properties as the original material may be used.

Safety nets and net accessories must be stored appropriately between two periods of use. Appropriate storage is given if they are

- in a dry environment,

- protected from UV radiation,

- protected from heat, and

- not stored in contact with aggressive substances (e.g. acids, alkalis, solvents, oils).

As supplied, safety nets are approved in accordance with EN 1263-1 for a maximum of 12 months from the date of manufacture. This approval can be extended three times for a net with an aging test for a further 12 months in each case. The time of the last test or the date of the next test is indicated on the type plate attached to the net.

There are test meshes on each construction net that can be clearly assigned to the net. For testing, one of these test meshes is detached from the net and sent to a suitable test center or the manufacturer. There, a tensile strength test is carried out. If this so-called test does not fall below the minimum energy absorption capacity specified by the manufacturer, the test is deemed to have been passed. The approval is then extended for a further 12 months. Proof of this is provided by the testing body by supplying a new nameplate for the network and issuing a test report.

The test of the minimum energy absorption capacity must be carried out in accordance with EN 1263-1 and must not date back more than 12 months. The results of tests on safety nets in use must be verifiably documented by the contractor.

Products

Further Guidelines & Info Pages