- Details

- Technical Specifications

- More Pictures

- Customer Pictures

- Reviews

Description

Suspension rope in conformity with EN 1263-1, Type L for one-strand suspension. Approved anchorage system for construction safety nets in conformity with

One end with a spliced loop, the other end is welded. In conformity with BGR 179, safety nets should be anchored to load-bearing suspension points at maximum intervals of 2.50 m. When using one-strand suspension ropes, the minimum breaking force of the ropes must be 30 kN.

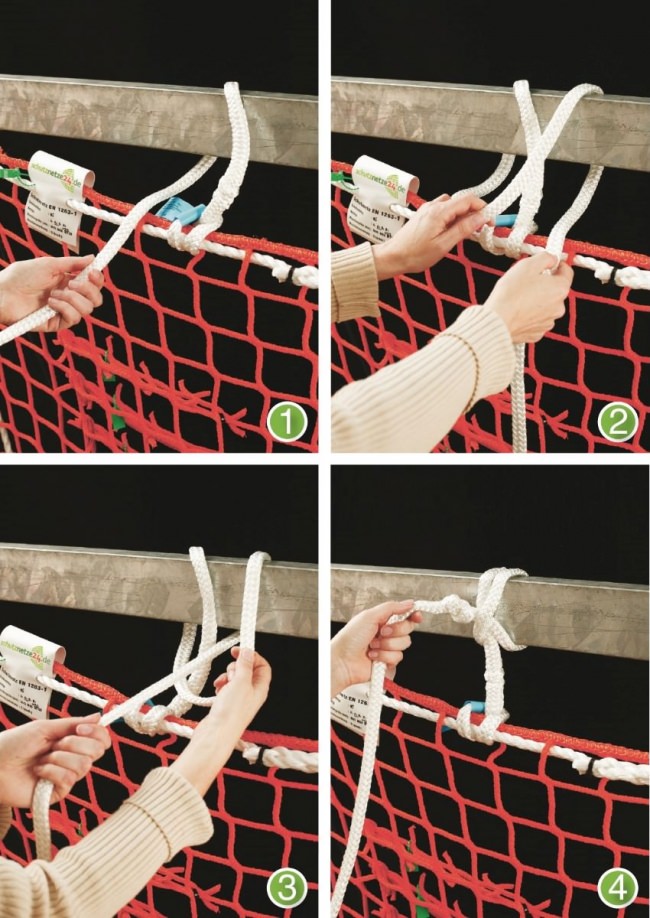

The side of the loop is affixed to the net. With the free end, the net is then knotted to the suspension point. The knot is usually a "clove hitch" (see sample picture).

| Safety Net Dimensions | Required Number of Suspension Ropes* |

|---|---|

| 3.00 x 3.00 m | 8 pcs. |

| 5.00 x 5.00 m | 8 pcs. |

| 5.00 x 10.00 m | 12 pcs. |

| 6.00 x 10.00 m | 14 pcs. |

| 10.00 x 10.00 m | 16 pcs. |

| 7.50 x 15.00 m | 18 pcs. |

| 8.00 x 25.50 m | 26 pcs. |

| 12.50 x 20.50 m | 28 pcs. |

| 12.50 x 25.50 m | 32 pcs. |

* Required quantity of ropes to mount fall safety nets at all four edges with a maximum interval of 2.50 m (referring to EN 1263).

Download product data sheet (PDF)

Our building site nets (fall safety nets, guardrail safety nets) are produced in conformity with the currently valid standards and regulations. The nets are certified in conformity with EN 1263-1, approved by the BauBG (German Building Trade Association) and have a test certificate.

Your satisfaction and safety are very important to us. Regular quality inspections guarantee the high standard of our products. Our nets and fabric are designed to fulfil the most exacting standards and are characterised by their exceptional durability.

Not sure which net thickness is right for your specific purpose or do you perhaps have a different question? Trust our many years' experience and contact us!

Customer Reviews

We have put a safety net over our pond to make it child-safe. Since there are small trees around it, we have also used the hanging rope as a method of attachment. We have used 3 ropes on different sides of the pond in addition to ground anchors and pegs. It is very stable and easy to use. translated, original text: "Wir haben ein Schutznetz über unseren Teich gespannt um diesen kindersicher zu machen. Da kleinere Bäume um diesen stehen, haben wir u.a. auch dass Aufhängeseil als Befestigungsmethode verwendet. Wir haben 3 Seile an verschiedenen Seiten des Teichs neben Erdankern und Heringen verwendet. Es ist sehr stabil und einfach zu verwenden."

Great, thanks for the good advice via email.

A net as a pool cover with the appropriate safety ropes (so that nothing rusts in the stainless steel pool) works great.

Regards AK translated, original text: "Super Danke für die gute Beratung per e-mail.

Netz als Poolabdeckung mti den passenden Sicherungsseilen (dass nix rostet im Edelstahlpool) funktioniert super.

lg AK"

Great quality. We are delighted with the net and the safety cord. Highly recommended! Very well made. translated, original text: "Super Qualität. Wir sind begeistert von dem Netz und der Sicherungsschnur. Nur zu empfehlen! Sehr gut verarbeitet."

Attach a safety net........

Fits so well that I'm ordering the next safety net straight away. translated, original text: "Ein Schutznetz befestigen........

Passt so gut das ich gleich das nächste Schutznetz bestelle."

Fall protection! Very stable and trustworthy. translated, original text: "Absturzsicherung! Sehr stabil und Vertrauenserweckend."

Very good quality and great price translated, original text: "Sehr gute Qualität und super Preis"

Quality and price just fit translated, original text: "Qualität und Preis passen einfach"

Attachment of a fall net. translated, original text: "Befestigung von einem Fallnetz."

Great material! Classy. translated, original text: "Super Material ! Klasse."

great safety net! translated, original text: "super sicherheits netz !"

modified eCommerce Shopsoftware © 2009-2026

Code & Implementation: Rehm Webdesign